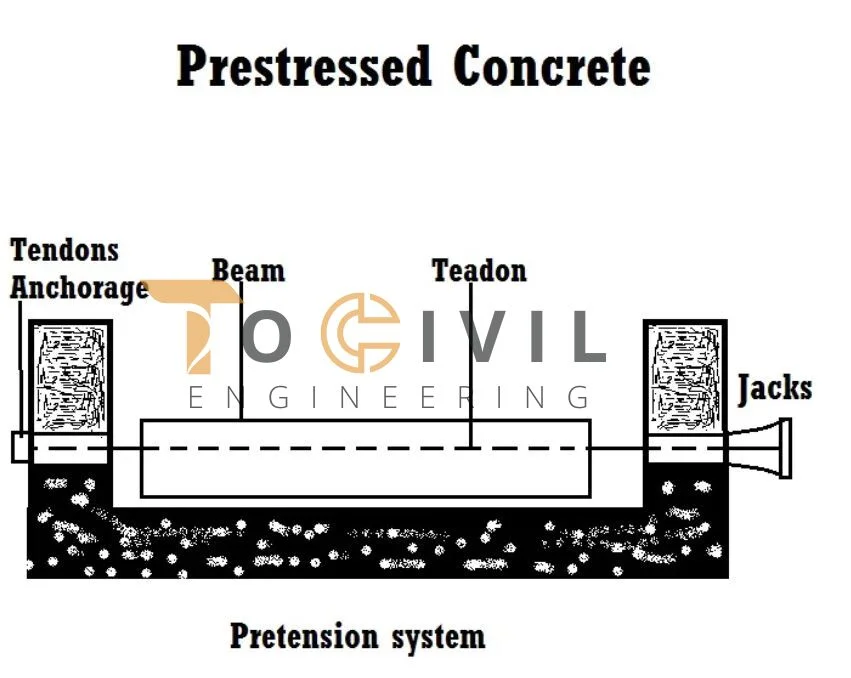

Introduction to Prestressed Concrete

Prestressed concrete is a structural material that employs steel tendons to induce predetermined engineering stresses within concrete members to counteract the stresses that will occur when loaded. It combines concrete’s high compressive strength with steel’s high tensile strength.

What is prestressed concrete?

Prestressed concrete is a concrete member subjected to internal stresses before use. These stresses are introduced into the concrete by tensioning steel tendons. Tendons are anchored at each end of the member and create a compressive force in the concrete when tensioned. This compressive force balances the tensile stresses caused by loading and helps to keep the concrete from cracking.

Basic principles of prestressed concrete

The following are the basic principles of prestressed concrete:

- Before the concrete member is cast, the steel tendons are placed within it.

- After the concrete has hardened, the tendons are tensioned.

- Tendons are attached to the member at both ends.

- The tendons’ tension exerts a compressive force on the concrete.

- The compressive force balances the tensile stresses caused by loading.

The structure and loading conditions determine the amount of prestressing force applied to a concrete member. Generally, greater prestressing force is required for structures subjected to higher loads.

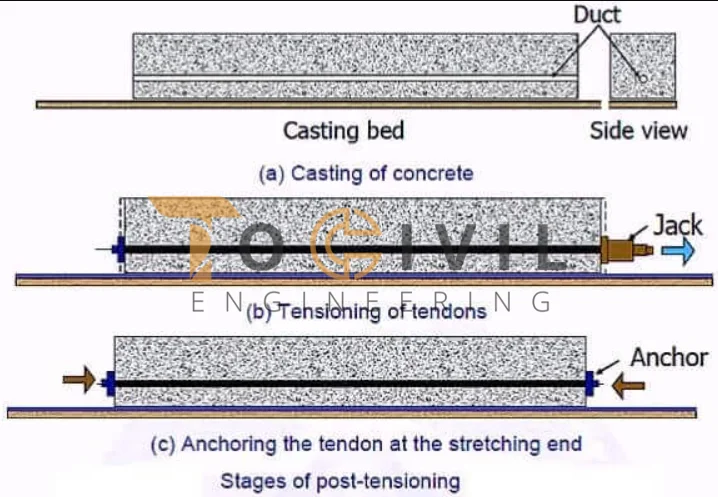

There are two ways to apply prestressing force: pre-tensioning and post-tensioning.

- The tendons are tensioned before the concrete is cast in pretensioning.

- The tendons are tensioned after the concrete has hardened in post-tensioning.

Precast concrete members are pre-tensioned, whereas cast-in-place concrete members are post-tensioned.

Types of Prestressed Concrete

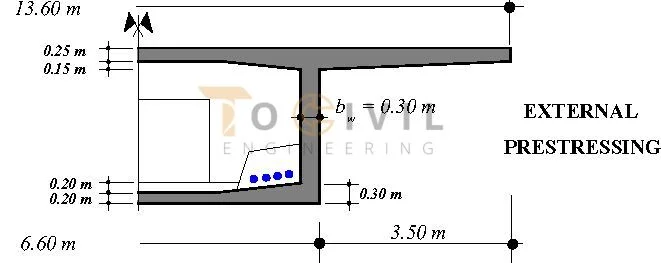

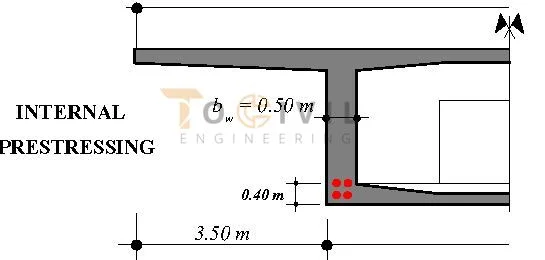

Prestressed concrete is classified into two types:

- External prestressing is a concrete prestressing in which the tendons are located outside the concrete member. This type of prestressing is typically used for high-load structures such as bridges and buildings.

- Internal prestressing is a concrete prestressing in which the tendons are contained within the concrete member. This type of prestressing is typically used for lower-load structures such as pavements and sidewalks.

External prestressing

There are two more types of external pre-tensioning:

- External prestressing with bonded tendons is a way to strengthen concrete in which the tendons are attached to the concrete part. This type of prestressing is usually used on buildings that have to handle heavy loads and vibrations.

- External prestressing with unbonded tendons is a way to strengthen concrete in which the tendons are not attached to the concrete part. This type of prestressing is usually used on buildings exposed to chemicals or high temperatures.

Internal prestressing

There are two more types of internal pre-stressing:

- In pre-tensioning, the tendons are tightened before the concrete is poured. It is a type of interior prestressing. Most of the time, this kind of prestressing is used on precast concrete parts.

- Post-tensioning is internal prestressing in which the tendons are tightened after the concrete has been set. Most of the time, this type of pretensioning is used on cast-in-place concrete parts.

Design and Construction of Prestressed Concrete

The design and building of prestressed concrete structures is a complex process that involves the following steps:

- Analysis of the loading factors: The first step is assessing the loading conditions the structure will be subjected to. It includes the dead load (the weight of the building itself) and the live load (the weight of people, vehicles, or other objects using the structure).

- Design of the prestressing method: Once the loading conditions are known, the prestressing system can be developed. It includes selecting the type of prestressing, the size and number of tendons, and the location of the tendons.

- Fabrication of the prestressing muscles: The tendons are then fabricated to the needed specifications. It may involve welding wires or strands together or wrapping a wire or strand around a core.

- Prestressing of the concrete: The tendons are then prestressed in the concrete part. It can be done using several methods, such as hydraulic jacks or a winch.

- Concreting: The concrete is then cast around the tendons. The concrete must be of high quality and must be cured properly to ensure that it has the needed strength and durability.

- Curing: The concrete must be set for some time to allow it to reach its full strength. It is usually done by keeping the concrete moist and warm.

Prestressing materials

Most of the time, the following things are used in prestressed concrete:

- Tendons of steel: Most of the time, prestressing is done with steel cables. They are made of strands or lines of high-strength steel.

- Concrete: When making prestressed concrete, the concrete used must be of good quality and have a high compressive strength.

- Grout: In post-tensioned concrete, the holes around the tendons are filled with grout. Cement, sand, and water are used to make grout.

Prestressing tendons

The tendons are the most essential part of a building made of pre-stressed concrete. They are responsible for getting the force from the prestressing to the concrete. The tendons have to be strong enough to stand up to the force of pre-tensioning, and they have to be tough enough to stand up to rust and wear.

There are two main kinds of muscles used to tighten something:

- A wire: The most usual way to stretch a tendon is with wires. They are usually 0.25 inches in diameter and made of high-strength steel.

- There are strands: Several wires are joined together to make a strand. Most of the time, they are 0.5 inches in diameter.

Prestressing anchorages

With the anchorages, the tendons are attached to the concrete part. They have to be strong enough to stand up to the force of the prestressing, and they have to be tough enough to stand up to rust and wear.

There are two main types of anchorages for pre-tensioning:

- Anchorages at the abutment: Abutment anchorages connect the tendons to the ends of the concrete section.

- Anchors on the outside: External anchorages are used to connect the tendons to the sides of the concrete section.

Prestressing bed

The concrete part is put on a surface called the prestressing bed during prestressing. It needs to be smooth and level to put the concrete part in the right place.

Most of the time, the bed is made of concrete or steel. It needs to be strong enough to hold the weight of the concrete part and the prestressing force.

Concreting

After the cords have been pulled tight, the concrete is poured around them. For the concrete to be strong and last as long as it needs to, it must be of good quality and properly cured.

Most of the time, a crane or a pump is used to put the concrete in place. Ensuring the concrete around the tendons is spread out properly is essential.

Curing

The concrete needs time to cure to reach its full strength. Most of the time, this is done by keeping the concrete warm and wet.

How long it takes to cure depends on the concrete type and weather. For curing the concrete, it’s important to follow the directions from the manufacturer.

Advantages of Prestressed Concrete

- Increased strength and stiffness: Normal concrete is less strong and stiff than pre-stressed concrete. It is because the force of the prestressing works against the tensile loads that would cause the concrete to crack otherwise. Because of this, prestressed concrete can be used to make thinner and lighter sections that can hold more weight.

- Reduced cracking: Normal concrete is more likely to crack than concrete that has been pushed. The prestressing force helps keep the concrete in compression, which keeps it from breaking. Because of this, prestressed concrete can be used in bridges and buildings that are put under a lot of tension.

- Longer service life: Normal concrete doesn’t last as long as pre-stressed concrete does. It is because the force of the prestressing helps keep the concrete from cracking, which can cause the steel support to rust. Because of this, buildings made of pre-stressed concrete can last for many decades.

- Lighter weight: The weight of pre-stressed concrete is less than that of regular concrete. This is because the prestressing force makes it possible to use less concrete. Because of this, buildings made of prestressed concrete can be cheaper to build and keep up.

- Wider design possibilities: More design options are available with pre-stressed concrete than with regular concrete. This is because the form and behavior of the concrete member can be controlled by how much force is used to stretch it. Because of this, prestressed concrete can be used to make bridges, houses, and dams, among other things.

Applications of Prestressed Concrete

Bridges

Prestressed concrete is used in many different types of bridges, such as:

- Long-span bridges: Long-span bridges are made of prestressed concrete because it is strong and light. It means longer spans can be made with less material, saving money.

- Arch bridges: Arch bridges are made with prestressed concrete because they can handle the high compressive stresses of this type of construction.

- Truss bridges: Truss bridges use prestressed concrete because it can be used to make lightweight sections that can hold a lot of weight.

- Cantilever bridges: Cantilever bridges are made with prestressed concrete because they can make long, thin pieces that hold much weight.

Buildings

Prestressed concrete is used in many different types of buildings, such as:

- High-rise buildings: High-rise buildings use prestressed concrete because it is strong and light. It means higher buildings can be made with less material, saving money.

- Industrial buildings: Prestressed concrete is used in industrial buildings because it is strong and can withstand hard conditions.

- Commercial buildings: Commercial buildings use prestressed concrete because it is flexible and can be used to make a wide range of shapes.

- Residential buildings: Prestressed concrete is used in household buildings because it is cheap and can be made to look like many different things.

Dams

Many buildings use prestressed concrete, such as:

- Gravity dams: Gravity dams are made out of prestressed concrete because they are strong and can handle the high compressive stresses of this type of building.

- Arch dams: Arch dams are made with prestressed concrete because they can handle the high compressive stresses of this type of building.

- Buttress dams: Buttress dams use prestressed concrete because it can be used to make lightweight members that can hold a lot of weight.

Tunnels

Prestressed concrete is used in many buildings, such as:

Road tunnels: Because they are strong and long-lasting, they are made of prestressed concrete.

Railroad tunnels: Because they are strong and last long, they are made of prestressed concrete.

Water tunnels: Water pipes are made of prestressed concrete because it is strong and doesn’t rust.

Pipelines

Many types of pipes use pre-stressed concrete, such as:

Water pipelines: Water pipes are made of pre-stressed concrete because it is strong and doesn’t rust.

Oil pipelines: Oil pipes are made of pre-stressed concrete because it is strong and doesn’t rust.

Gas pipelines: Gas pipes are made of pre-stressed concrete because it is strong and doesn’t rust.

More Articles

FAQ’s

What is the difference between Prestressed and Post tensioned concrete?

1. In Pre-tensioning, the reinforcement is stretched across the concrete formwork using tendons or cables before the concrete is poured. After the concrete has hardened and reached the right level of strength, the tendons are removed.

2. Post–tensioning is a type of prestressing in which the tendons are tightened after the concrete has hardened, and most of the prestressing force is transferred to the concrete through the end anchorages.

What is Prestressed Concrete?

Prestressed concrete is concrete that has been pre-stretched so that the forces inside the concrete counteract the forces from the outside to a certain degree. Members made of reinforced concrete can be put in one of two groups:

1. pre tensioned

2. post-tensioned.

What is the name of concrete pipe?

Reinforced concrete pipes, called RCP pipes, are precast and available in various diameters. They are used for stormwater drainage and other applications which require a high degree of structural integrity. Concrete pipe is a rigid pipe with outstanding strength and increased longevity (life in the range of 70 to 100 years)

How is prestressed concrete cylinder pipe made?

In this type of Prestressed Concrete Pipe, a concrete core pipe is lined with a steel cylinder wrapped with a helix of highly prestressed wire. A coat of cement mortar or dense concrete protects this wire arrangement. At each end of a steel cylinder are steel joint rings that connect two pipes when the cylinder is being put in place.

What is the difference between mass concrete and reinforced concrete?

The reinforcement is the main difference between mass concrete and reinforced concrete.

1. Mass concrete is weak in tension because it has nothing to hold it up.

2. Reinforced concrete is mostly strong in both compression and tension. The reason for this is that the steel and concrete stick together.