Girder Bridge

- A girder bridge is a type of bridge that is constructed using girders as the main load bearing structure.

- Girders are large horizontal beams that are designed to support the weight of the bridge deck and any traffic or loads that cross over it.

- Girder bridges can be made of different materials including steel, concrete or timber and can be designed in various shapes and sizes to accommodate different spans and traffic loads.

- The familiar types contain box girder bridges, plate girder bridges, tubular girder bridges and I-beam girder bridges.

- Girder bridges are widely used in transportation infrastructure, including highways, railways, and pedestrian walkways.

Define Girder Bridge

“It is a type of bridge that utilizes beams known as girders to support the weight of the bridge deck. The girders are made up of steel or concrete and are put perpendicular to the direction of the bridge. Girder bridges are mostly used for short to medium span lengths, typically up to 300 feet“.

Girder

It is a horizontal or sloping structural member that supports the weight of a bridge, building or other structure by spanning an open space such as a roadway or a river. Girders are made up of steel or concrete and are build to oppose bending and shear forces. They are attached with other structural elements such as columns and beams to build a larger structure.

Steel Girder

A steel girder is a horizontal structural element used to construct buildings, bridges, and other structures. It is made of steel and typically has an I beam or H beam cross-section. Steel girders are created to support the weight of the structure like bridge deck, the roof of a stadium or the floors of a building. Steel girders are mostly used in construction projects that require long spans or high strength as they offer excellent strength-to-weight ratios and are resistant to bending and deflection.

Girder truss

A girder truss is designed to function as a load-bearing element in construction projects such as bridges, buildings, or other structures. A top and bottom chord is connected by a series of diagonal members forming triangles. A girder truss and a regular truss vary primarily in that the former has a greater overall depth and is capable of supporting heavier loads over longer spans. Girder trusses are commonly made from steel, timber or concrete and are often utilized in bridge and roof construction where a strong, lightweight and cost effective solution is required.

The Beam

A beam is a structural element designed to resist bending and support loads perpendicular to its longitudinal axis. They come in a different forms and sizes depending on their use. They are built from diverse materials including steel, wood or concrete. They are commonly used to support floors, roofs, and walls and span gaps between two supports in bridge construction. The design of a beam depends on factors such as the load it will support, the span length, and the material used.

Beam Bridge

A beam bridge consists of one or more horizontal beams spanning an open area, supported at either end by abutments or piers. The beams can be made from various materials including timber, steel or concrete and are typically designed to resist bending and compression forces. Beam bridges are utilized for short to medium spans and are the simplest and most cost effective type of bridge to construct.

Types of Bridges

There are several types of bridges as follows

- Beam bridges: A simple type of bridge that consists of a horizontal beam supported by piers at each end.

- Truss bridges: These bridges are composed of interconnected triangles that distribute loads between the supports.

- Arch bridges: These bridges have a curved shape and rely on the arch’s compressive strength to support the bridge’s weight.

- Suspension bridges: These bridges have tall towers and large cables that suspend the bridge deck from the towers.

- Cable-stayed bridges: Similar to suspension bridges, but with cables that connect the bridge deck directly to the towers, rather than suspending it.

- Cantilever bridges: These bridges have two or more arms extending from each pier and supporting the bridge deck’s weight.

- Tied-arch bridges: These bridges have an arch tied to the ends of the bridge deck, providing support and stability.

Parts of a Bridge

Bridges typically consist of several key parts, including:

- Foundation: The base of the bridge that supports the weight of the entire structure.

- Abutments: The supports at either end of the bridge that holds up the weight of the bridge deck.

- Piers: Vertical supports that are located underneath the bridge deck and provide additional support.

- Deck: The bridge surface vehicles or pedestrians use to cross over the gap.

- Girders or trusses: Structural elements that support the bridge deck and transfer the load to the abutments or piers.

- Bearings: Devices that allow the bridge deck to move slightly and adjust to changes in temperature and weight.

- Expansion joints: Gaps in the bridge deck allow for expansion and contraction due to temperature changes.

- Railings or parapets: Protective barriers on the sides of the bridge deck that prevent vehicles or pedestrians from falling off.

A specific design of bridge and components can vary depending on factors such as the span length, the load it will carry and the construction materials and techniques used.

Design and construction of Girder Bridge

This process consist of several steps that must be carefully followed to confirm the safety and durability of the structure.

- Determine the Bridge Requirements

The first step in constructing a girder bridge is to choose the requirements of the bridge including the span length, width and vertical clearance. The type of traffic and the weight of vehicles crossing the bridge must also be considered. - Select the Bridge Type

There are several girder bridges, including concrete, steel, and composite bridges. The choice of material will depend on cost, durability, and maintenance requirements. - Determine the Bridge Layout

The layout of the bridge must be determined. It contains the number of girders needed, the spacing between them and the size of the piers that will keep the bridge upward. - Design the Girders

The girders must be created to withstand the weight of the bridge deck and the burdens placed on it by traffic. It involves determining the girders’ appropriate size and shape and the reinforcing bars’ spacing. - Fabricate the Girders

The girders are fabricated once the design has been finalized. It involves cutting and shaping the steel or concrete to the required specifications. - Construct the Substructure

The substructure of bridge including the piers and abutments, must be constructed to support the bridge’s weight. It involves pouring concrete or building masonry walls to the required height. - Install the Girders

The girders are transported to the site and installed on the piers. It involves lifting the girders into place using cranes and bolting them to the abutments. - Install the Bridge Deck

The bridge deck is installed once the girders are in place. It involves laying the concrete or steel decking on top of the girders and reinforcing it with steel bars. - Finish the Bridge

The final step is to finish the bridge, which may include painting, adding guardrails, and installing lighting.

Types of Girder Bridge

There are different types of girder bridges having their own advantages and disadvantages. The main types are explained below.

Steel Girder Bridge

Steel girder bridges are the most common for medium to long spans. They are made of steel girders arranged in a series and span across a river, highway, or valley. Steel girder bridges are lightweight, durable and easy to maintain which make them a popular choice for engineers and builders.

Types of Steel Girder Bridges

- Plate Girder Bridges

Plate girder bridges are made of a series of steel plates welded together to form a girder. They are used for shorter spans and can be easily fabricated off-site. - Box Girder Bridges

Box girder bridges are similar to plate girder bridges, but the girders are enclosed in a box-shaped structure. It provides greater stiffness and reduces the amount of deflection, making them suitable for longer spans. - Tubular Girder Bridges

Tubular girder bridges are circular or rectangular tubes welded together to form a girder. They are commonly used for long spans and provide excellent resistance to wind and earthquake forces.

Design

- Span Length

In order to support the weight of the bridge deck, it will select the size and shape of the steel girders. - Traffic Load

It is important to consider the amount and kind of the traffic that will use it because this will have an impact on strength and longevity of the girder. - Foundation

The bridge’s foundation must be designed to support the weight of the steel girders and the bridge deck.

Construction

- Fabrication

The steel girders are fabricated off site and transported to the construction site. - Erection

The steel girders are lifted into place using cranes and bolted to the abutments and piers. - Decking

The bridge deck is installed on top of the steel girders and reinforced with steel bars. - Finishing

The bridge is finished with guardrails, lighting, and surface treatment.

Advantages

- Lightweight

Steel girders are much lighter than concrete girders, which reduces the weight on the bridge’s foundation and makes construction easier. - Durable

Steel is highly resistant to corrosion, rust, and weathering, which makes steel girder bridges long-lasting and low maintenance. - Easy to Fabricate

Steel girders can be easily fabricated off-site and transported to the construction site, which reduces construction time and cost.

Disadvantages

Steel girder bridges require regular maintenance to ensure their durability and safety. Maintenance activities may include cleaning, painting, and inspection for signs of corrosion or structural damage.

Concrete Girder Bridge

A concrete girder bridge is a type of bridge that uses precast concrete girders as the primary structural element to support the bridge deck. These bridges are common on highways and other transportation routes and span short to medium distances. Concrete girder bridges have several advantages, including high durability, low maintenance, and reduced construction time.

Types of Concrete Girder Bridge

- Precast Concrete Girder Bridge

It is a bridge that uses precast concrete girders that are produced off-site and transported to the construction site for assembly. - Cast-in-Place Concrete Girder Bridge

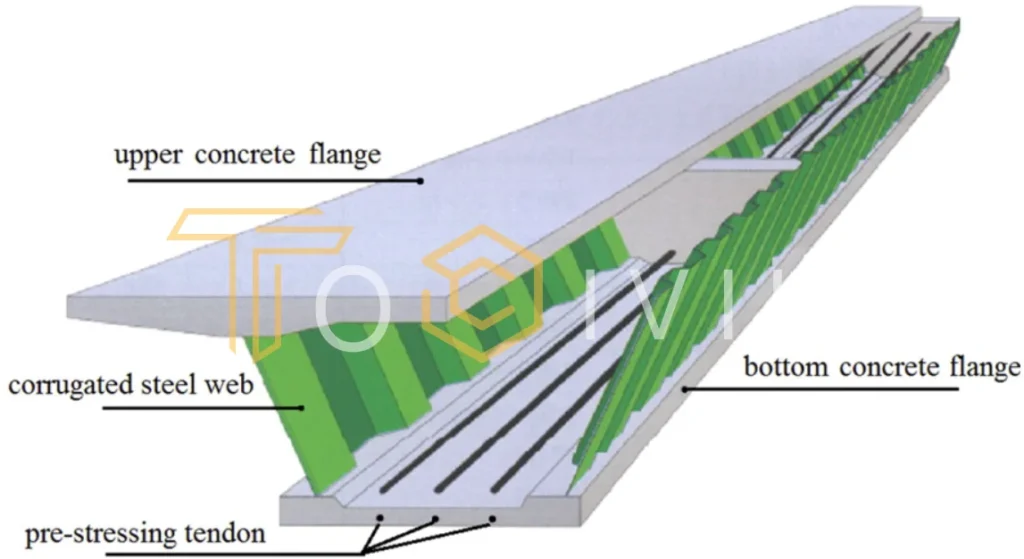

It is a bridge where the girders are constructed on-site using formwork and then filled with concrete. - Prestressed Concrete Girder Bridge

It is a bridge where the concrete girders are manufactured with prestressing tendons to increase their strength and durability. - Box Girder Bridge

It is a bridge where the girders have a hollow box-like shape and can be made of reinforced or prestressed concrete. - T-beam Girder Bridge

It is a bridge where the girders have a T-shaped cross-section and are commonly used for shorter spans.

Design

The design of a concrete girder bridge is typically based on several factors, including the span length, the expected loads, and the site’s environmental conditions. The girders can have various shapes, such as rectangular or trapezoidal, and can be prestressed or reinforced with steel bars.

Construction

- Site preparation

The site is cleared and excavated to provide a level surface for the bridge’s construction. - Foundation construction

The foundations for the bridge are built, typically using concrete piers or abutments. - Girder fabrication

The precast concrete girders are fabricated off-site and transported to the construction site. - Girder placement

The girders are lifted into place using cranes and secured to the bridge abutments and piers. - Deck construction

The bridge deck is constructed once the girders are in place, typically using cast-in-place concrete or precast concrete slabs. - Finishing touches

The finishing touches, such as railings and pavement markings, are added to the bridge.

Advantages

- Durability

Concrete is a durable material that withstands harsh weather conditions and heavy traffic. - Low maintenance

Concrete girder bridges require little maintenance over their lifetime, reducing long-term costs. - Reduced construction time

Precast concrete girders can be fabricated off-site, reducing construction time and minimizing disruption to traffic. - High strength-to-weight ratio

Concrete girders have a high strength-to-weight ratio which makes them ideal for spanning longer distances.

Disadvantages

- Limited span length

Concrete girder bridges are typically used for shorter to medium spans and may not be suitable for longer spans. - Limited design flexibility

The design of concrete girder bridges is often limited by the available precast girder shapes and sizes. - Initial cost

Concrete girder bridges may have a higher initial cost than other bridges, but their long-term durability and low maintenance costs can offset this.

Truss Girder Bridge

A truss girder bridge is a type of bridge that uses a series of interconnected triangles to support the bridge deck. Truss bridges are commonly used for longer spans and can be made from various materials, including steel and concrete. The design of a truss girder bridge is based on several factors, including the span length, the expected loads, and the site’s environmental conditions.

Types of Truss Girder Bridge

- Precast Concrete Girder Bridge

It is a bridge that uses precast concrete girders produced off-site and transported to the construction site for assembly. - Cast-in-Place Concrete Girder Bridge

It is a bridge where the girders are constructed on-site using formwork and then filled with concrete. - Prestressed Concrete Girder Bridge

It is a bridge where the concrete girders are manufactured with prestressing tendons to increase their strength and durability. - Box Girder Bridge

It is a bridge where the girders have a hollow box-like shape and can be made of reinforced or prestressed concrete. - T-beam Girder Bridge

It is a bridge where the girders have a T-shaped cross-section and are commonly used for shorter spans.

Design

A truss girder bridge design typically involves selecting the appropriate truss configuration based on the span length and expected loads. Truss configurations can vary, but common types include Pratt, Warren, and Howe trusses. They can be made of steel or concrete and are typically fabricated off site and transported to the construction site.

Construction

- Site preparation

The site is cleared and excavated to provide a level surface for the bridge’s construction. - Foundation construction

The foundations for the bridge are built, typically using concrete piers or abutments. - Truss fabrication

The trusses are fabricated off-site and transported to the construction site. - Truss placement

The trusses are lifted into place using cranes and secured to the bridge abutments and piers. - Deck construction

The bridge deck is constructed once the trusses are in place, typically using cast-in-place concrete or precast concrete slabs. - Finishing touches

The finishing touches, such as railings and pavement markings, are added to the bridge.

Advantages

- Long spans

Truss bridges are well-suited for longer spans and can be designed to accommodate a variety of loads. - High strength-to-weight ratio

Truss bridges have a high strength-to-weight ratio which make them ideal for spanning longer distances. - Design flexibility

Truss bridges can be designed with various truss configurations, allowing for flexibility in design. - Durability

They are made of long lasting materials like steel or concrete and can resist harsh weather conditions and heavy traffic.

Disadvantages

- Cost

Truss bridges can be more expensive than other bridges due to their complex design and fabrication process. - Maintenance

Truss bridges require regular inspection and maintenance to ensure long-term durability. - Aesthetics

Some people discover the formation of truss bridges to be less visually appealing than other types of bridges.

More Post

FAQ’s

How many bridges in Pittsburgh?

Pittsburgh is known for having many bridges with some estimates putting the number at over 446 bridges within the city limits. The exact number of bridges in Pittsburgh can vary depending on how they are counted, as some smaller bridges or pedestrian crossings may not be included in certain counts. However, regardless of the exact number, it’s clear that Pittsburgh has a rich history of bridge building and many bridges crossing its rivers and valleys.

What factors can weaken a beam bridge?

Corrosion: If the steel or other materials utilized to build the bridge are exposed to water or chemicals, they can corrode over time which can weak the structure.

Overloading: Beam bridges are designed to support a specific weight limit, and overloading the bridge with heavier vehicles or loads than it was designed for can cause damage or collapse.

Fatigue: Repeated loading and unloading of the bridge over time can cause fatigue in the materials, leading to cracking or other structural damage.

Environmental factors: Bridges can be subject to severe weather conditions such as high winds or heavy snow which can stress the structure more.

Poor maintenance: If a bridge is not properly maintained and inspected, problems can go unnoticed and worsen over time, leading to potential structural weaknesses.

How to build a beam bridge?

1- Design and plan the bridge based on site location, traffic volume, and expected loads.

2- Construct the abutments and piers that will support the bridge beams.

3- Install the bridge beams by lifting them into place with a crane or assembling them on-site.

4- Add any necessary deck or roadway surfaces, safety barriers and other features to complete the bridge.

How does a beam bridge work?

A beam bridge works by distributing the bridge’s weight and its load across a series of horizontal beams supported by piers or abutments at either end. When weight is applied to the bridge, the beams transfer the load to the supports, distributing the weight into the ground.

Why triangles are used in bridges?

Triangles are used in bridges because they provide structural stability and strength. Triangles are the strongest shape in geometry because they distribute weight evenly and reduce stress on individual points. It makes them ideal for bridge construction, where the structure’s weight needs to be supported by the underlying framework. When a triangle is subjected to external forces, the force is evenly distributed across all three sides which means that no single point is under too much stress. In bridge construction, triangles are often used to form trusses or support structures that withstand heavy loads and stress.

What is pier cap in bridge?

A pier cap in a bridge is a horizontal structure that sits on top of a pier or column and provides a base for the bridge deck. It distributes the deck’s weight evenly across the pier and helps transfer the loads from the deck to the supporting structure. Pier caps are typically reinforced concrete designed to resist bending and shear forces.