Wood Joints

Wood joints are made from pieces of wood using glue, pegs, fasteners, or nails as the joining agent. These joints join wood, engineered lumber, or synthetic substitutes (like laminate) to create more intricate items.

Various other methods can be used to produce wood joints, and they vary depending on the type of joint needed. Some joints must have a channel carved into them by two pieces of wood to lock them together, while fasteners like nails or screws hold others together.

A woodworker can choose from various woodworking joints when creating multiple pieces of furniture, flooring, and other items out of wood. The woodworker now has a variety of inventive options.

Types of Wood Joints

This article will explain the various types of wood joints and how they work. All of their benefits and applications are explained.

The following are the various types of wood joints:

Butt Joint

A butt joint is the most basic type of wood joint. The term “butt” refers to the timber board’s end. It is the simplest and weakest joint in woodworking, formed by joining two squared-off pieces of wood at a right angle.

Mechanical fasteners such as nails, screws, glue, or dowels hold the two parts together at the butt joint, unlike other wood joints.

Butt joints are commonly seen in construction projects around baseboards and window trims, and they are an excellent choice when the speed of construction is more important than joint appearance.

Miter Joint

“Miter” is a different term for an angled cut, and it describes two 45-degree cuts where two pieces of wood meet to form a 90-degree angle.

Miter joints are frequently used on the visible outer corners of door frames, window frames, and picture frames. They are more durable than butt joints because two wood pieces are joined on a larger surface area, but glue and mechanical fasteners are still required to keep them in place.

The strength and seamless appearance of the corner created using this technique without end grain are advantages.

Half-Lap Joint

The ends of two pieces of wood that are joined together are cut down to half their thickness, where they overlap in a half-lap joint. Half-lap joints are stronger than butt joints but look better because they are consistent.

It is commonly used when a connection requires to be made in the middle of the wood. Half-lap joints are widely used in both furniture manufacturing and framing.

Tongue and Groove Joint

Another well-known woodworking joint is the tongue and groove, which is used in paneling, parquetry, and wood flooring, among other things.

A channel or groove on one piece of wood and a tongue or ridge on the other make up these joints. To create a sturdy joint, the tongue is designed to slide into the groove.

Usually, components that rest flat on a surface, like wood flooring, have these joints.

Dado Joint

The tongue-and-groove joint is similar to the dado joinery method. The only distinction is that a groove is cut along the grain of the wood, typically down the length of the board, whereas a dado is cut across the grain. In addition, a wider groove is cut to fit the thickness of the other piece instead of carving a tongue along the edges.

Most of the time, bookshelves and other types of shelving use Dado’s joints.

Dovetail Joint

This woodworking joint has high resilience (the resistance to being pulled apart) and excellent tensile strength. They are made up of several interlocking pins with trapezoidal tails.

They are most frequently used to build drawers because of their crucial characteristic: their resistance to being pulled apart. There is no need for mechanical fasteners once the joint has been glued because it is permanent.

Finger Joints

The finger joint is also called the box junction. It is one of the most popular joints used in woodworking. This kind of wood joinery technique’s primary goal is to combine two pieces of wood to produce a longer board. The finger joint and a dovetail joint are similar except for the pins being square rather than angled.

Since finger joints lack the mechanical strength of a dovetail, glue is used to hold the joint together.

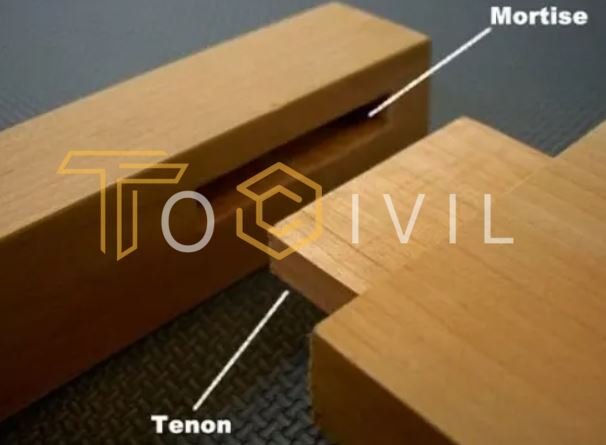

Mortise and Tenon Joint

The strongest wood joints for framing and construction are mortise and tenon joinery. One end of the piece (Tenon) is inserted into a hole (mortise) in the other part to form a 90-degree connection between two pieces of wood.

This joint is held together by glue, and once it has dried, it can be fastened with a pin or wedge. It is a much more powerful and sophisticated substitute for a butt joint.

Biscuit Joint

This joint is an improved butt joint with an oval shape. A biscuit is made from dried and compressed wood. The timber piece has a groove carved into both ends to hold a tiny wafer that will act as a connector. The insert will grow to fill the void left by the carving tool after applying the glue.

This joint’s advantage is that it completely vanishes, creating a flush surface. The mortises for the biscuit joiners were cut incorrectly, and the alignment of the joint could be better.

Rabbet Joint

The edge of the timber is carved to create a recess, which forms the joint. Except that only one side has been cut, it resembles the projecting edge of a tongue-and-groove joint. Despite being a straightforward wood joint, the rabbet joinery is much more durable than the butt joint.

The two most common applications for a rabbet joint are to lessen the amount of “end grain” visible on a corner or to recess a cabinet back into the sides.

Due to its larger surface area, a Double Rabbet is the best choice if one needs a stronger joint.

Pocket-Hole Joint

An essential butt joint is held with screws at an angle in pocket-hole joinery. The gap between the two boards must be prepped by the woodworkers with a pilot hole. A screw holds the two pieces together, giving the wood a flat surface.

The construction of pocket-hole joints is quick and easy. They are better suited for temporary use or situations where the joint won’t be visible due to their aesthetic disadvantage compared to other joints.

On face frames and cabinet doors, this technique is frequently employed. Home archways and door jambs may occasionally have pocket joints as well.

Sliding Dovetail Joint

Two boards can be joined at right angles in the field of one panel rather than the end using a sliding dovetail. The interlocking strength of a dovetail is made possible by this design. The tail is slid into the socket to assemble this style of wood joint.

Sliding dovetail joints are adaptable joints with a wide range of uses. It is mechanically robust, offers many glue surfaces, is comparatively simple to make, and looks nice when put together. All you need to create this wood joint is a router, a router table, and a dovetail bit.

Scarf Joint

It is a method of joining two members end-to-end in woodworking, also known as a scarf joint. If you have long pieces of lumber, a scarf joint is an excellent choice. It makes a 45-degree angle with the elevation at the end of a board where two pieces meet, resulting in a seamless transition between parts.

This joint is frequently preferred over other joinery joints because, unlike the butt and splice joints, it produces a barely visible glue line. These types of wood joints are primarily used to construct boats and canoes.

Cross-Dowel Joint

These look a lot like dowel-type wood joints. The only difference is that a threaded metal dowel now occupies the drilled slot. A screw is inserted and tightened in this joint to create a pull effect, commonly used in factory-made furniture.

Cross-dowel joints create strong, secure right-angle joints that can withstand high torque. Disassembling and reassembling this joint several times may not lose strength or wear out from friction.

Advantages of Wood joints

- Strength: Woodworking joints provide strength and stability to the structure of the finished product. They ensure the joints are strong enough to withstand heavy loads and stress. They make the structure durable and long-lasting.

- Flexibility: Different types of wood joints can be used to create flexible connections between pieces of wood.

- Aesthetics: Wood joints can also enhance the appearance of a finished product. Some joints, such as the dovetail joint or the mortise and tenon joint, are visually appealing and can add a decorative element to the design.

- Durability: By creating a solid connection between pieces of wood, joints can help improve the finished product’s overall durability. This can be particularly important when the wood is subjected to heavy use or wear.

- Versatility: There are many types of wood joints, each with unique characteristics and advantages. This makes wood joints versatile for various woodworking projects, from furniture making to cabinetry to construction.

Disadvantages of Wood joints

- Complexity: Some types of wood joints can be complex, requiring advanced skills and specialized tools.

- Weakness: While many types of wood joints can provide strong connections between pieces of wood, some joints may need to be stronger than others. For example, a butt joint or a lap joint may not be as strong as a dovetail joint or a mortise and tenon joint.

- Limited flexibility: While some types of wood joints can provide flexibility, others may be more rigid, which can be a disadvantage in some situations. For example, a fixed joint may not be appropriate for a structure subjected to significant temperature or humidity changes.

- Appearance: While many types of wood joints can enhance the appearance of a finished product, some joints may need to be more aesthetically pleasing to everyone. For example, a biscuit joint may be solid and functional but may have a different visual appeal than a dovetail joint.

- Durability: While wood joints can improve the overall durability of a finished product, some joints may be less durable than others. For example, a dowel joint may be less stable than a mortise and tenon joint, mainly if the dowels need to be installed properly.

More Posts

FAQ’s

What are the best joints to use for wood?

The best joint for wood depends on factors such as the project type, strength required, and aesthetic appeal desired. Some commonly used joints for wood include butt joint, mortise and tenon joint, dovetail joint, lap joint, biscuit joint, and finger joint. The choice of joint will ultimately depend on the specific requirements of your project.

What is the basic wood joint?

A butt joint is a basic wood joint. It is the simplest and most basic joint when two pieces of wood are joined at their ends. This joint is created by simply butting the ends of two pieces of wood together and securing them with nails, screws, or glue. However, the butt joint is not very strong and not recommended for load-bearing or heavy-duty applications.

What is the strongest wood joint?

Mortise and tenon joint is a most strongest joint. This joint involves a projecting tenon from one piece of wood fitting into a corresponding mortise in the other piece of wood. The mortise and tenon joint provides a large surface area for glue and allows for mechanical interlocking of the two pieces of wood.

What is the oldest type of wood joint?

The oldest known type of wood joint is the mortise and tenon joint, which woodworkers have used for thousands of years. Ancient Egyptians first developed the joint, and it has been found in furniture and construction projects from ancient Greece, Rome, and China. The mortise and tenon joint is still widely used today. It is a strong and durable joint that can withstand heavy loads and resist pulling forces.

Which is No 1 wood?

Maple is sometimes considered the best wood for furniture because of its excellent stability and attractive grain.

Hard maple is primarily used for hardwood flooring because it is more difficult to cut and wears down tools. But soft maple is one of the best woods for furniture.

What joints are used in furniture?

Six types of joints are commonly used in furniture depending on the piece’s style and purpose. Some common wood joints used in furniture include:

1. Mortise and tenon joint

2. Dovetail joint

3. Finger joint

4. Butt joint

5. Rabbet joint

6. Dado joint

What are the 5 main joints?

The 5 main joints used in woodworking are:

1. Butt joint

2. Lap joint

3. Mortise and tenon joint

4. Dovetail joint

5. Miter joint

What is the difference between groove and slot?

Grooves are commonly used to create joints such as the tongue and groove joint. It involves a projecting tongue on one piece of wood fitting into a corresponding groove on another.

Slots are commonly used to receive hardware or other materials, such as a drawer slide or a biscuit joint.