“The procedure known as “Bar Bending Schedule (BBS)” entails cutting, bending, and fixing reinforcement bars in accordance with a drawing.”

- In construction projects, the Bar Bending Schedule (BBS) is an essential part of reinforcement detailing.

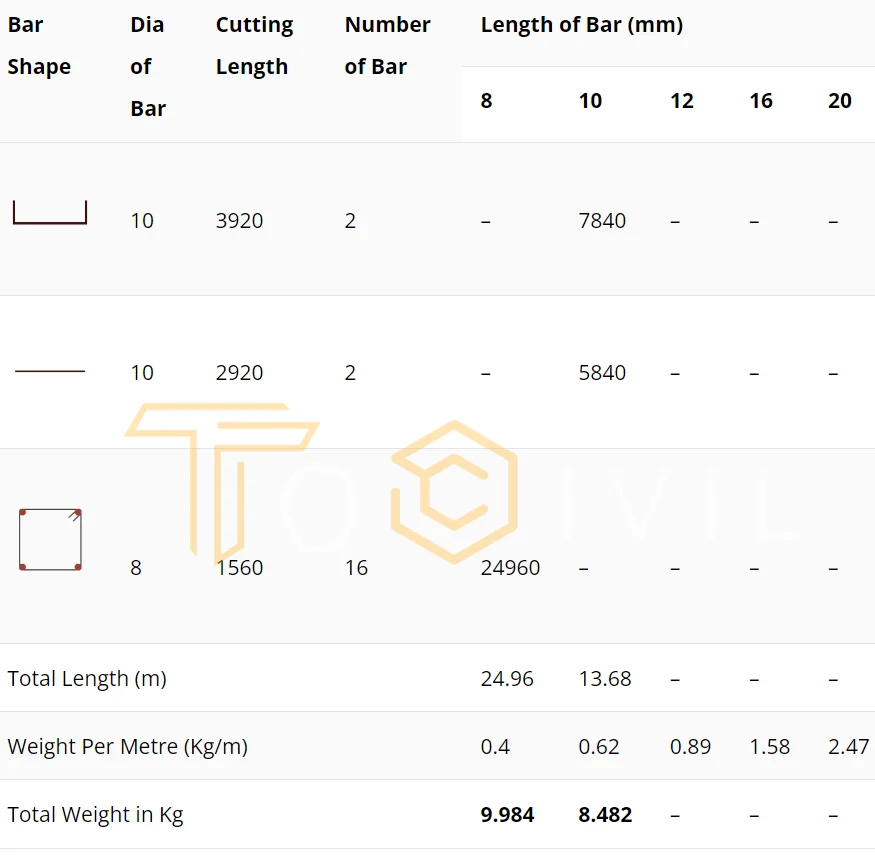

- Regarding the size, quantity, cutting lengths, and placement of reinforcement bars, the BBS provides comprehensive information.

- Reducing waste and excess materials through precise calculations, aids in resource optimization.

- The BBS improves coordination and communication between parties involved in the building process.

- Offering precise instructions for fabricating and installing reinforcement bars, helps save time.

- The BBS is essential to the quality control and inspection procedures that guarantee adherence to design requirements.

- Technology development has resulted in the creation of specialized software tools for developing and managing BBS.

What is Bar Bending Schedule

A bar bending schedule, which includes a mark, the shape, size, location, length, and bending details of the reinforcement, is a comprehensive list of reinforcement bars for any structural element. BBS is a common abbreviation for it.

BBS refers to a tabular view representation of every reinforcement bar used in any structural element.

Preparation of Bar Bending Schedule (BBS)

A schedule of bars, also known as a bar bending schedule (BBS), is a table-formatted list of the reinforcement bars needed for a specific reinforced concrete work item.

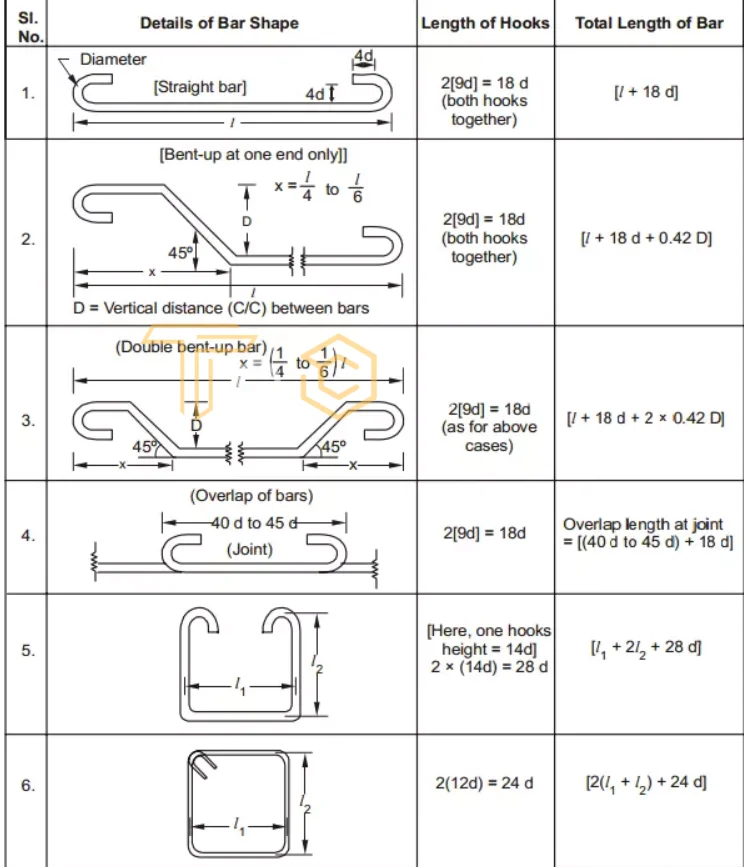

The diameter, shape, length of each bent and straight portion, angles of bending, total length of each bar, and quantity of each type of bar are all listed in the table of the bar bending schedule. Making a quantity estimate is made much easier with the help of this information

Bar Bending Schedule Is Code

Any bar or fabric listed in the schedule should have a total length in multiples of 25mm, and individual bends should have lengths in multiples of 5mm.

The code recommends a minimum radius “r” of bending depending on the diameter of the bar. This value for the minimum radius r must be kept in mind while scheduling.

Format of Bar Bending Schedule as per Code IS:2502-196

| Type | Mark Designation | Size and Type |

|---|---|---|

| Column | C4 4R 25 N | MS Road 25 mm |

Different Types of Rebars in BBS

The following terms are frequently used in BBS Civil to describe the various types of rebar (reinforcing bars) that may be used in a construction works project:

Main Bar

This is the rebar used as the primary reinforcement in a concrete element, such as a beam or a column. The main bar is the largest and strongest rebar in the element, and it is responsible for carrying the majority of the load.

Distribution Bar

This term refers to smaller rebar used to distribute load from the main bar to the concrete.

Distribution bars are commonly used in conjunction with main bars, and they are frequently spaced at regular intervals along the main bar’s length.

Bent-Up Bar

This is rebar that has been bent at an angle and is anchored to the concrete. Bent-up bars are frequently used to add reinforcement at the ends of beams or at high stress points in the element.

Stirrups

These are small rebars that give the main bars lateral support. Stirrups are typically bent into circular or square shapes and positioned at regular intervals along the main bars.

Extra Bars

These are additional rebar that may be required at specific points in the element, such as high stress points or the ends of the element.

Hooks

These are the rebar’s bent ends, which are used to secure it to the concrete. Standard hooks must be included in the bar bending schedule as they are typically specified in the design drawings or the construction specifications.

Helical Bars

This is rebar that has been twisted into a spiral shape and is used to provide additional reinforcement to concrete elements, particularly columns.

Anchor Bar

This is rebar that is used to hold the ends of other rebars in the element together. Anchor bars are typically used to add reinforcement at the ends of beams or at high stress points in the element.

Types of Steel Reinforcement

The following three steel reinforcement bar types are most frequently used in structural construction projects, though there are other types as well:

FE-250

Bars have a 250 MPa (megapascals) yield strength. They are frequently employed in low-rise buildings and other constructions with light loading demands.

FE-415

The yield strength of bars is 415 MPa. They are used in structures with moderate loading requirements, such as medium-rise buildings.

FE-500

The yield strength of bars is 500 MPa. They are employed in high-rise structures and other constructions requiring heavy loads.

Bending Schedule Formulas

Bar Bending Schedule Format

Advantages of Bar Bending Schedule

- Accuracy in Reinforcement Detailing: The BBS provides precise details regarding the size, placement, and shape of reinforcement bars. As a result, errors and discrepancies in the construction process are minimized and accurate reinforcement detailing is ensured.

- Optimal Resource Utilization: The BBS assists in maximizing the use of resources by precisely calculating the quantity of reinforcement bars required. It reduces waste and surplus materials, which saves money and makes construction more environmentally friendly.

- Time and Cost Savings: The BBS makes effective planning and coordination possible. The fabrication and installation processes can move along without hitches if there are clear guidelines and comprehensive information available, which reduces construction delays and saves time and money.

- Enhanced Communication and Coordination: The BBS serves as a common reference document for all project stakeholders, including architects, engineers, contractors, and fabricators. It promotes clear communication and coordination, ensuring that everyone is aware of the reinforcement requirements and placement details.

- Quality Control and Inspection: The BBS serves as a valuable tool for quality control and inspection processes. It provides a reference for inspectors to verify that the reinforcement bars are installed correctly as per the design requirements, ensuring adherence to quality standards.

More Posts

FAQ’s

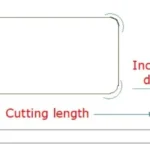

What is cutting length in bar bending schedule?

1 . The first is the Actual Length of a stirrup bar, and the second is the cutting Length.

2. The actual length is always shorter than the cutting length.

3 . When making stirrups, you’ll need to cut bars based on the cutting length.

What is bar bending schedule?

A bar bending schedule, or BBS as it is also known, is a detailed document that describes the type, size, mark, location, length, number, and bending details for all rebar required for a construction project. In other words, it allows for proper material management, reduces off-cut waste, and ensures that it is properly placed.

What is the length of lapping?

The tension forces must then be transferred from one bar to the other bar at the location of the bar’s discontinuity. As a result, the second bar is kept close to the first bar and overlapped. “Lap length” refers to the amount of overlap between two bars. Lapping is usually done where there is little bending stress. Lap length is generally 50d, which means 50 times the bar diameter if both bars are the same diameter. Usually, we use a maximum of 12m or 40ft bar length in construction. So lap is mostly provided after 12m or 40ft.

What is minimum radius of bend?

It is calculated from the inside of the bend. It’s important to know it’s the minimum diameter, not the radius. The minimum diameter for a #4 bar is 3 inches (1.5″ radius). The minimum diameter for a #5 bar is 3.75″ (1.875″ radius).

What is the minimum length of bend?

The minimum length of a bend depends on various factors, like material being bent, thickness, type of bending process, and equipment being used. The minimum length of a bend is usually greater than the material’s thickness. As a rough guideline, a minimum bend length of 1.5 to 2 times the material thickness is often recommended for precision bending.